Upgrading your system

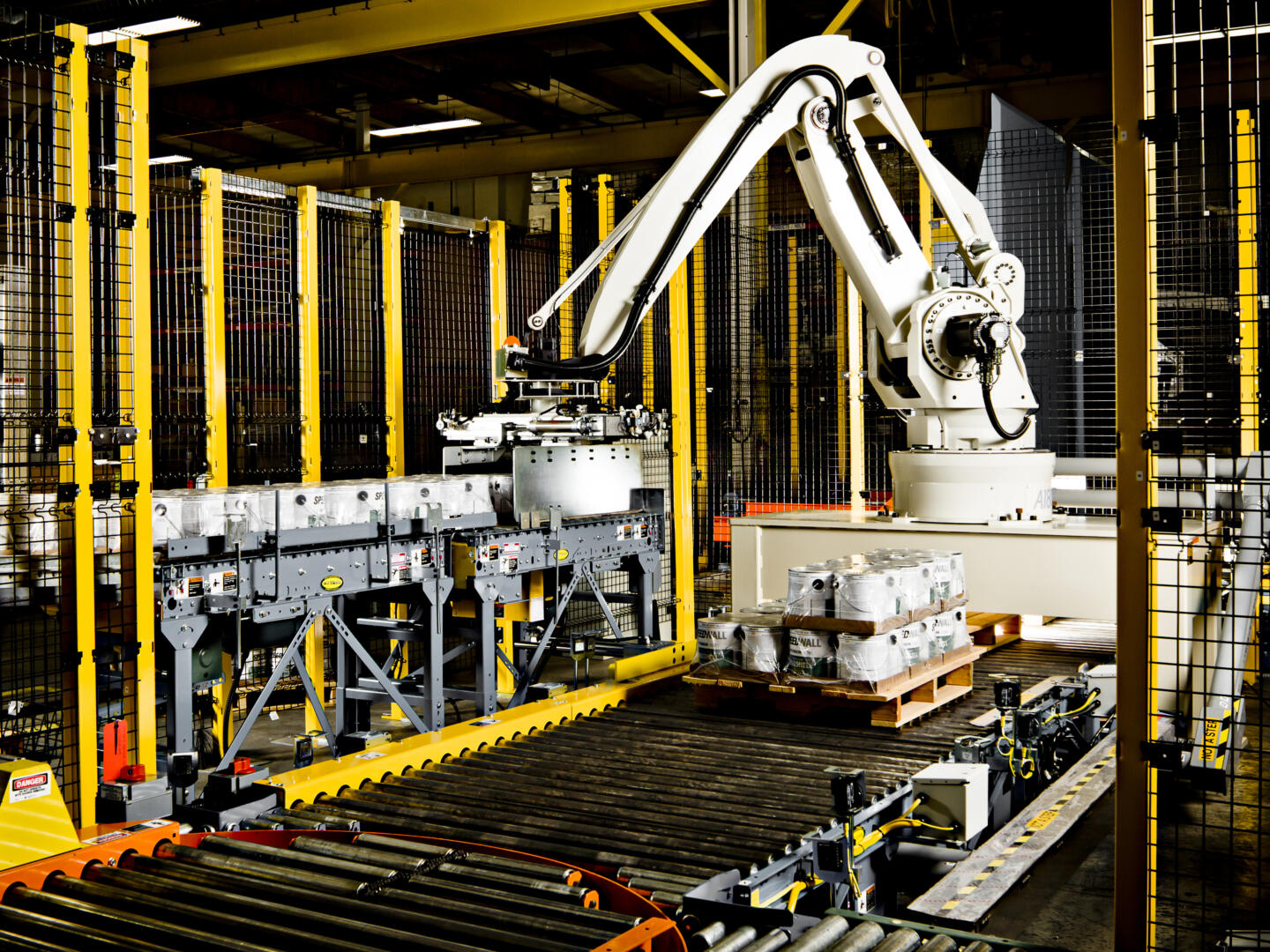

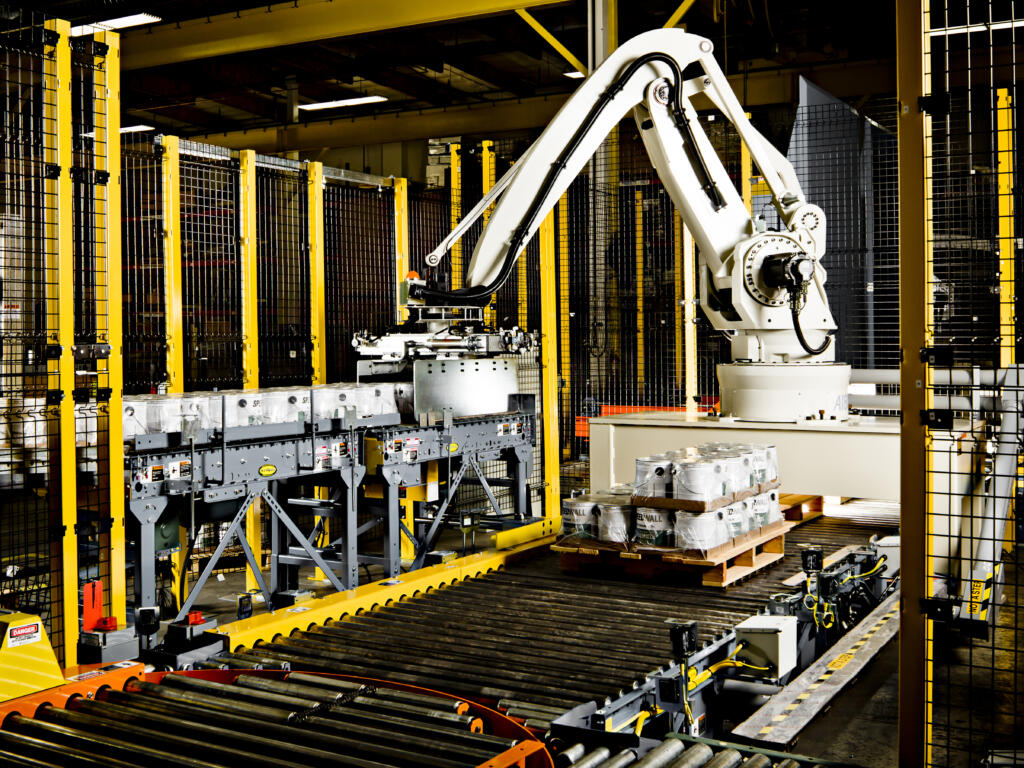

We understand that our customers operate in a dynamic environment, and flexibility is a significant factor when making the decision to purchase a robot for your end-of-line palletizing needs.

Whether you seek to increase the productivity of your current system, revise production configurations, or handle new load types, Columbia/Okura stands ready and able to assist with your changing requirements.

Packaging needs continue to evolve. Automation technology continues to improve. Let us help you upgrade your system to enhance productivity, comply with new packaging requirements, and/or new safety standards. Modifying your system with these upgrades may be far more cost effective than acquiring a new system.

Retrofits & Systems Enhancement Catalog

Our latest Retrofits & System Enhancement Catalog outlines adjustments, improvements, and different tools that can be added to your palletizing system.

Decision Time: Palletizing System Modification, Robot Replacement, or New Equipment

Is your robotic palletizing system keeping up with your business? Growing production, new products, and aging equipment can all necessitate a change. Do you modify your existing system, replace the robot, or invest in a brand new setup?

Our blog post breaks down the pros and cons of each option, helping you make the best decision for your needs. Read more to explore your choices and optimize your palletizing process!

Find answers to common questions about retrofitting your existing palletizing system with robotics.

Is retrofitting the right decision for my existing automatic palletizing system?

Given rising materials costs and existing space constraints, retrofitting can be a cost-effective alternative to installing a new palletizing system from the ground-up.

Robots are perfectly poised to solve the end-of-line palletizing challenges of:

- Boosting efficiency

- Increasing throughput

- Improving accuracy

- Solving labor shortages

Other common reasons to retrofit are to improve employee safety, meet new packaging applications, and improve pallet loads. Your company’s end goal, therefore, is a key factor in weighing the benefits of retrofitting. Other considerations include:

- Available floor space

- Upstream and downstream equipment

- Existing workflows and processes

Our expert team will work with you to recommend the best solution.

Our packaging has changed due to market shifts. Can my automatic palletizing system be modified to continue running at peak performance?

Yes! We offer retrofitting precisely for this reason. Our team can outline what equipment will work with your new application(s) to meet all current minimum safety requirements.

How do I know which equipment in my automatic palletizing system needs to be upgraded?

From a site visit and listening session, we will understand your application needs. Our team will conduct an audit on your existing palletizing equipment, ensuring it meets all current minimum safety requirements. Following the audit, we will suggest which equipment should be upgraded and what equipment your line may benefit from adding.