For nearly 30 years, we have been a leading provider of robotic palletizing systems by delivering custom engineered solutions to meet demanding customer requirements.

We support your decision-making with robust service so you can be confident you’re choosing the right system–and partner.

Product Demo: Ship us your product to run on our demo machines. On a video call or in person, we’ll show you our robotic palletizing capabilities.

Cost: Let us help you make the business case to add automation with a comprehensive cost evaluation, including total cost of ownership and return on investment.

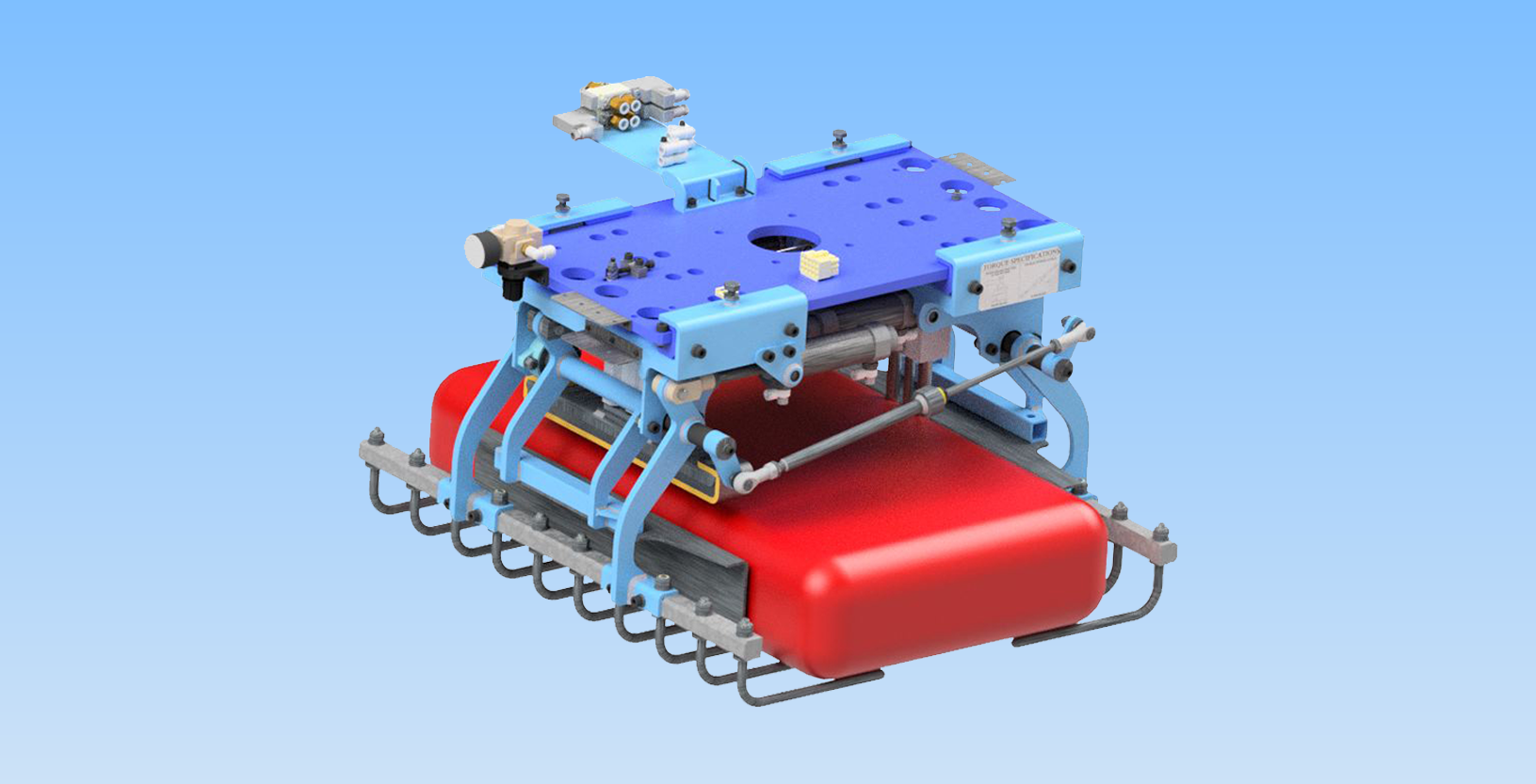

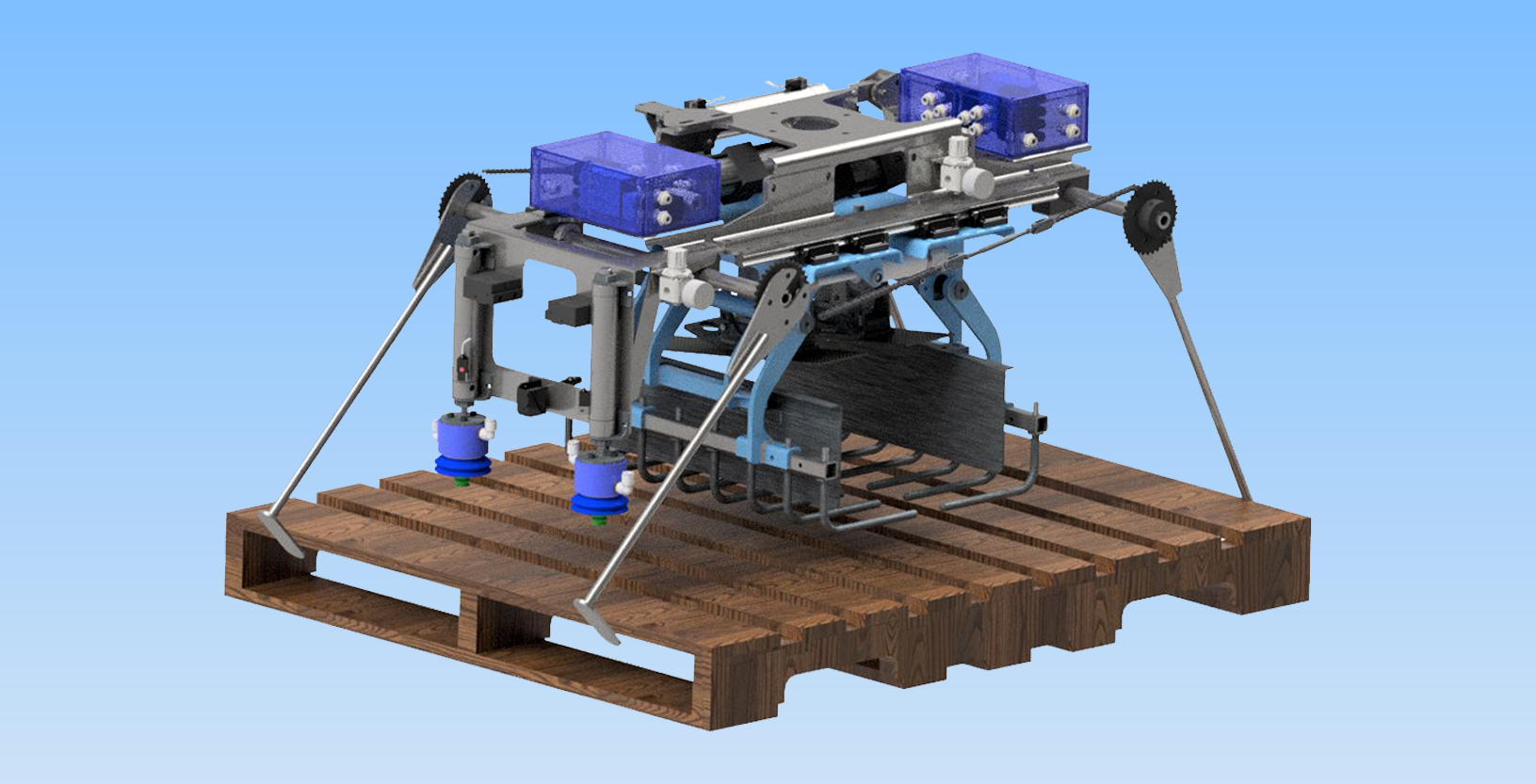

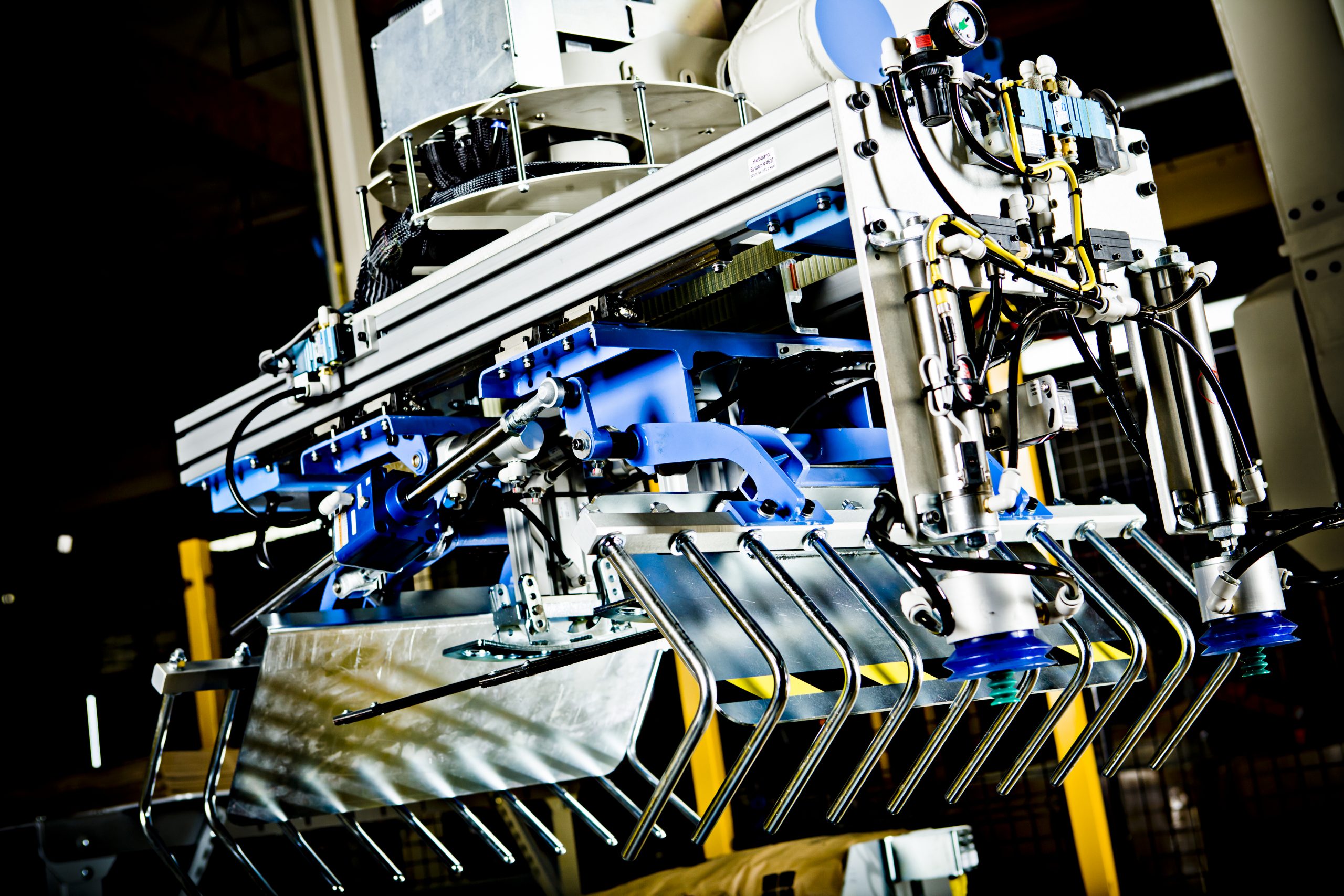

Custom Approach to End effectors

Our end effectors are meticulously engineered for speed and accuracy, optimizing your entire palletizing process. We analyze your specific products and palletizing patterns to design EOATs that are custom to your application and move with efficiency. They securely grasp, lift, and place your products with speed and accuracy, building stable and secure pallets every time.

Our EOATs are built with robust materials and rigorously tested to ensure consistent performance, cycle after cycle. This means you can rely on your palletizing system to deliver predictable results and minimize downtime due to equipment malfunction, promising rock-solid pallets built faster than ever before.

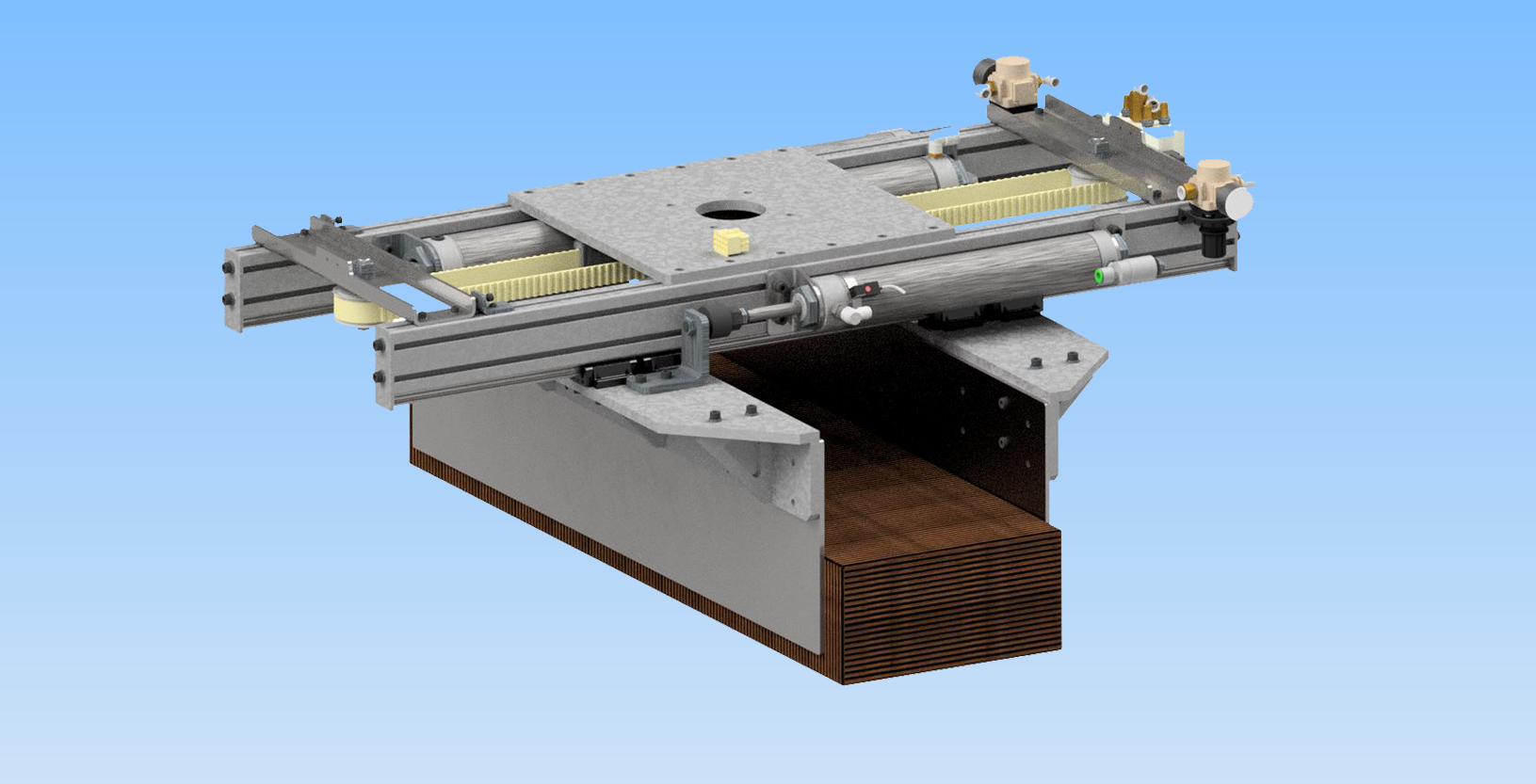

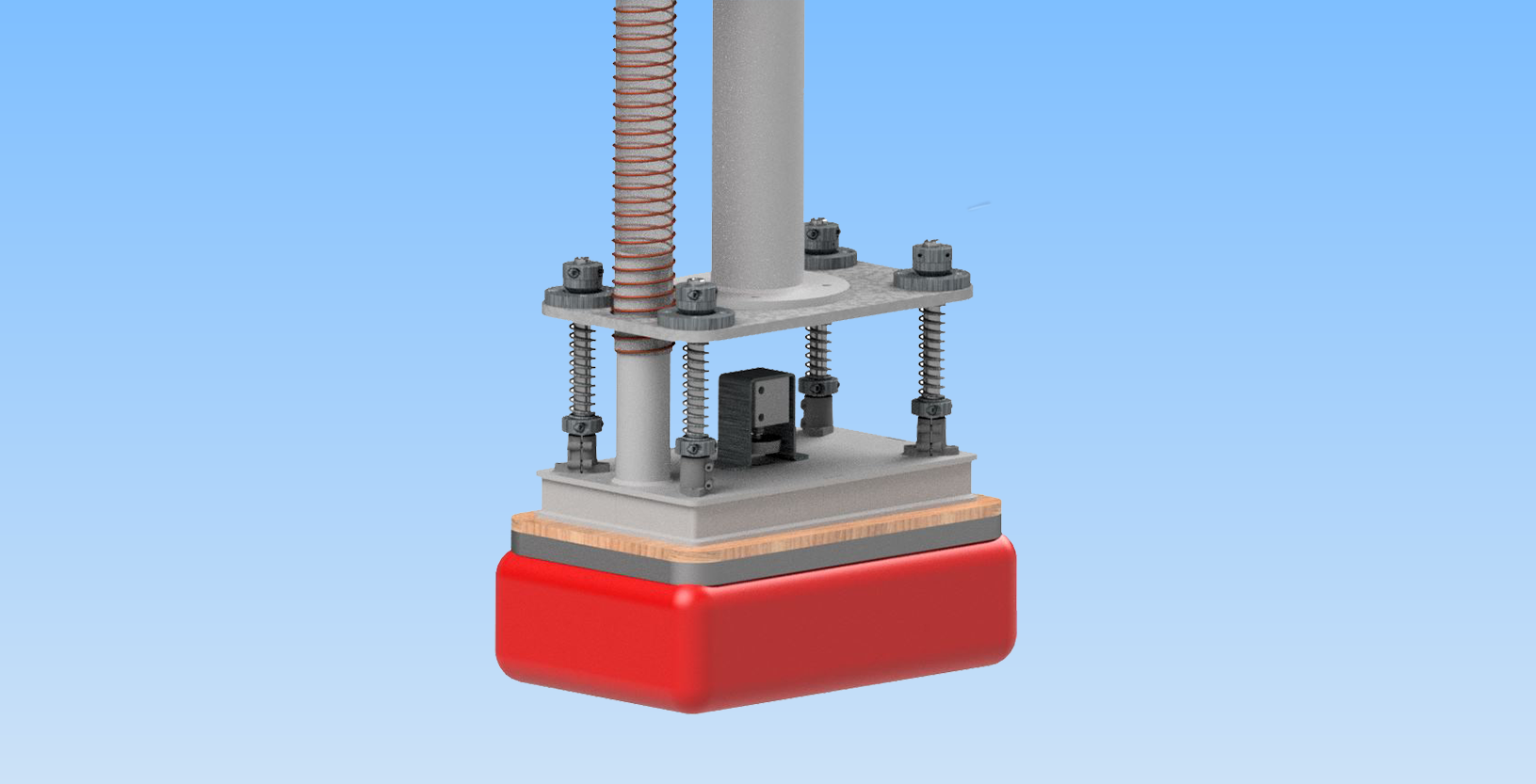

Pallet Handling

Pallet dispensers are an integral part of most palletizing systems ensuring a pallet is always ready for a robotic palletizer to place products.

Since 1996, we’ve been integrating industrial robot palletizers with upstream and downstream equipment, including automated pallet dispensers, helping our customers to increase throughput and solve work shortages.

Our pallet dispensers are assembled in the USA by our partner Columbia Machine, Inc.

Three methods to pallet dispenser we offer:

- Striper-Style

- Lift & Separate

- Staging (Fork Style)

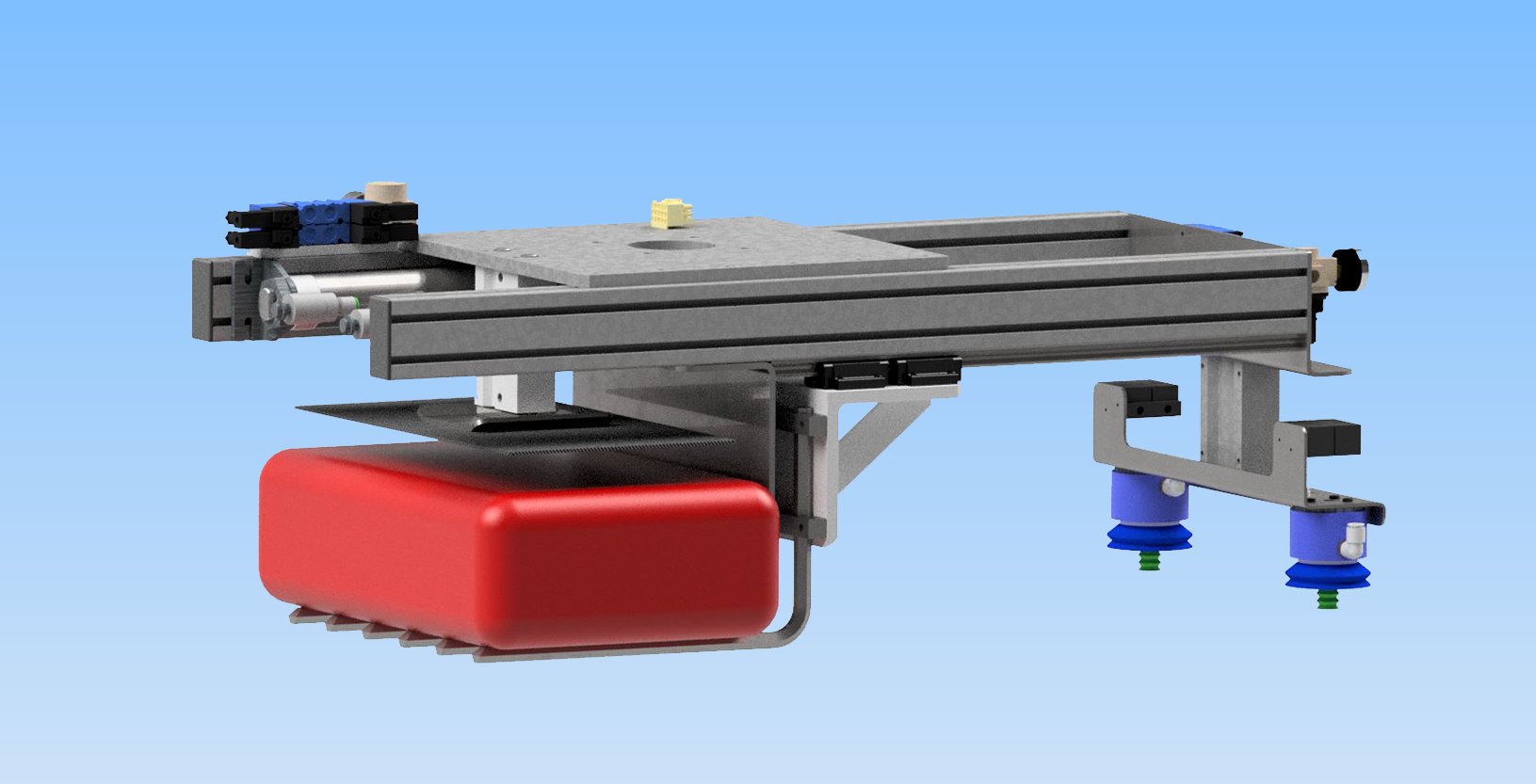

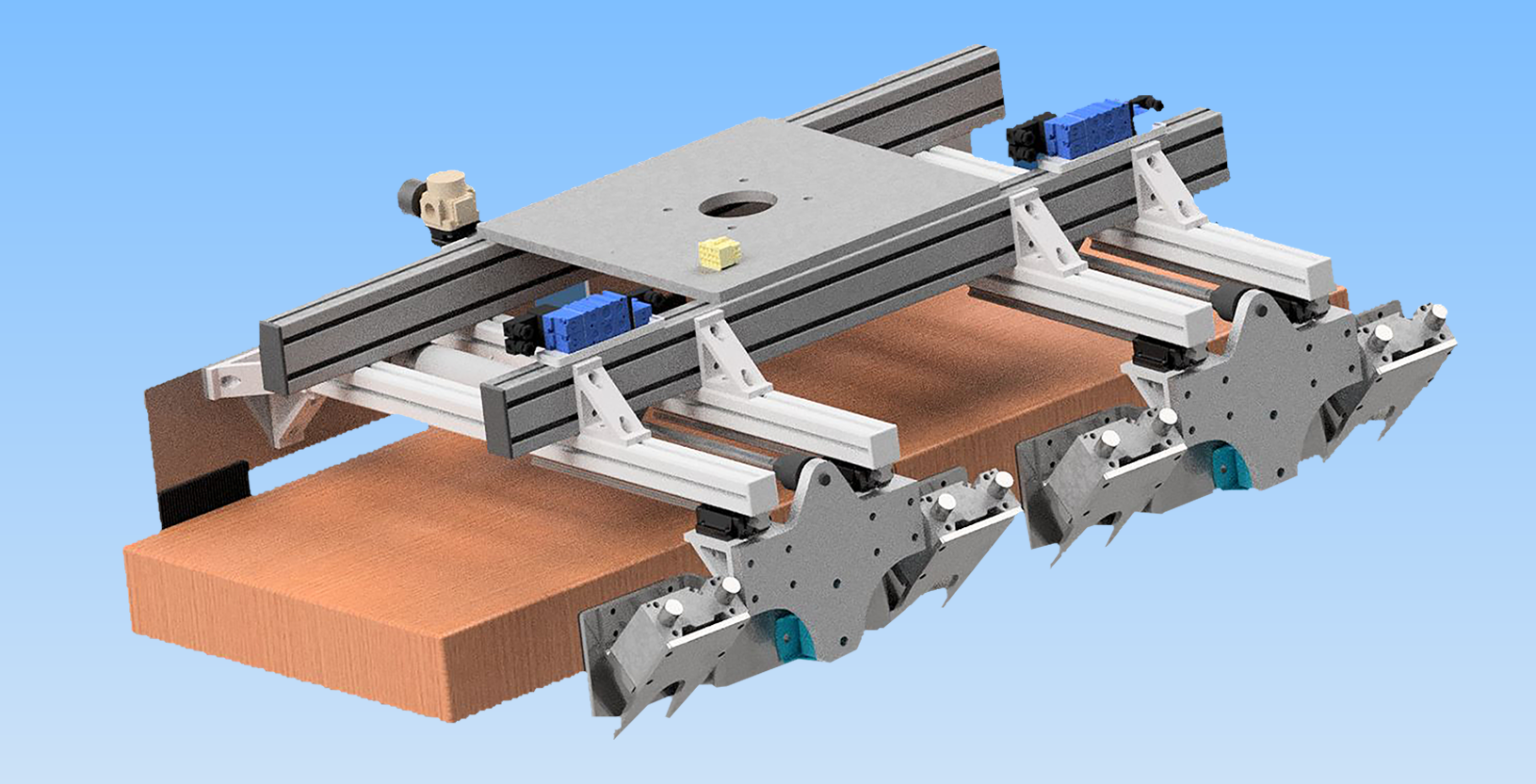

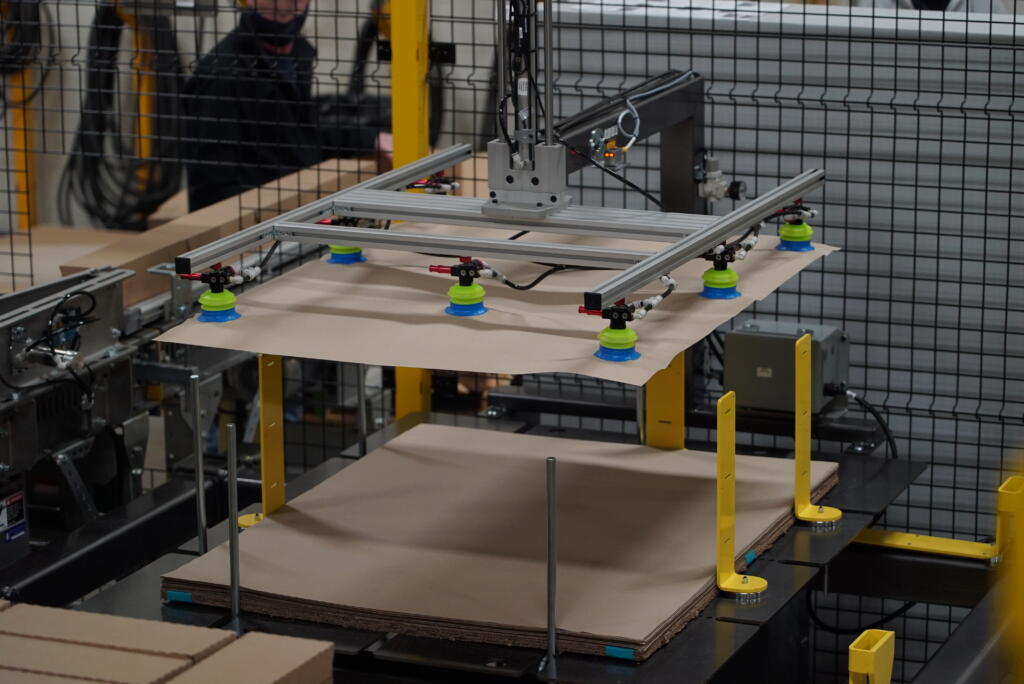

Sheet dispensers

Sheet dispensers are a vital component of many end-of-line systems, automatically dispensing sheets of material, like cardboard, paper, or plastic, onto pallets or product stacks. These sheets add a layer of protection, separation, or stability depending on the application for transit and storage.

Sheet dispensers come in various configurations to handle different sheet sizes and materials. Our team will work with you to understand your application to integrate you sheet dispenser seamlessly with our robotic palletizers for a smooth, automated workflow.

We can handle:

- slip

- tie

- cap sheets

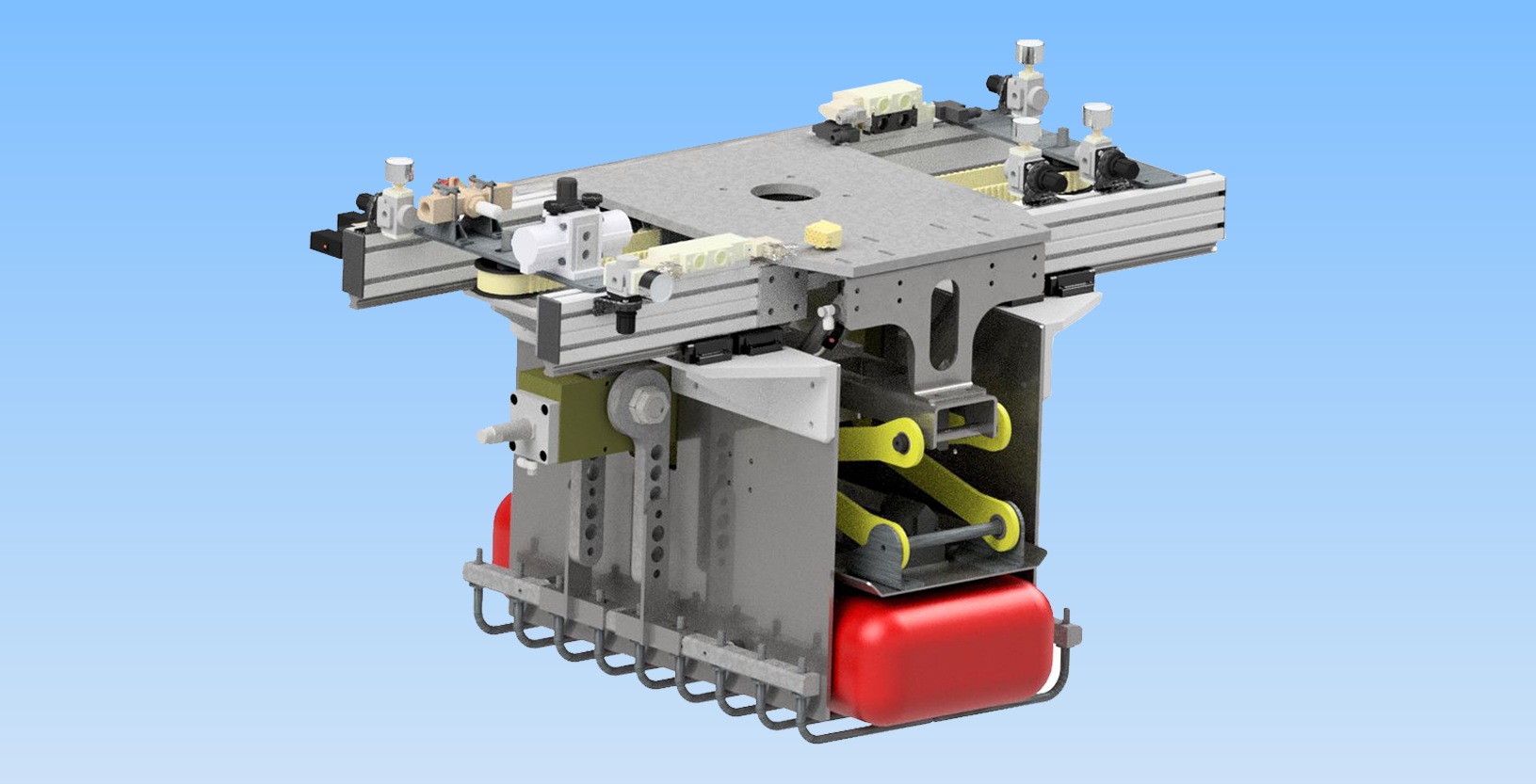

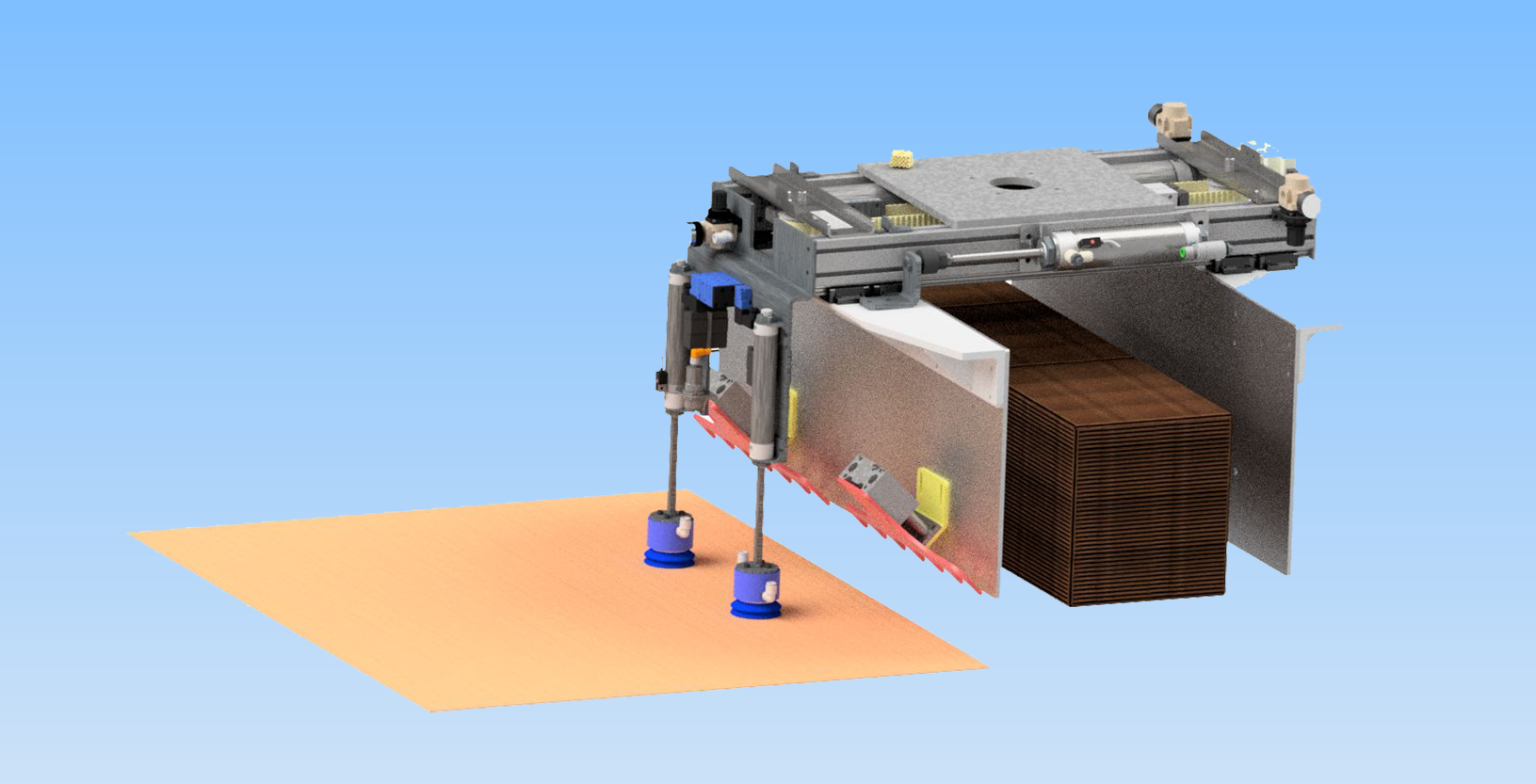

Product Handling

When it comes to product handling at the end of your production line, we understand that different products require different approaches. That’s why Columbia/Okura offers custom solutions and tools to ensure your specific needs are met.

Our expertise extends beyond palletizing robots. We can design and integrate custom tools for product orientation, ensuring every item arrives at the palletizer in the correct position. For delicate bagged products, we offer bag conditioning systems that gently manipulate and reshape bags, preventing damage and creating a uniform presentation on the pallet. And for efficient sorting and distribution, we can incorporate customized sorting mechanisms that seamlessly integrate with your existing line, directing products to the appropriate palletizing stations or packaging lines. With Columbia/Okura, your end-of-line system becomes a customized symphony of efficiency, ensuring smooth product handling from production line to perfect pallet.

We offer solutions that include:

- Product orientation

- Bag conditioning

- Product sortation

Safety

With decades of industry leading experience and expertise we understand safety requirements, compliance, and the importance of safety for your employees. We put safe practices and operations at the forefront of everything we do, enabling us to deliver the safest solutions for your facility.

Our integrated lines include safety features such as:

- Guarding

- Guarding bollards

- Light curtains

- Mechanical disconnect

- Radar

- Trapped key

About Us

For nearly 30 years, we’ve been helping our customers become more competitive, cost-effective, and productive in a fast-changing world.

Our Partnership Promise

From installation to 24/7 technical trouble-shooting, you’re getting a complete support and service team you can always rely on.