Our Partnership Promise

From custom-engineered solutions to complete integration to ongoing support, you can count on us to support your growth and success as if it were our own.

While the equipment in your system will be robotic, working with us is not. We’re committed to maintaining a long-lasting, collaborative partnership focused on meeting your unique needs.

Making Your Decision

We support your decision-making with robust service so you can be confident you’re choosing the right system–and partner.

Product Demo: Ship us your product to run on our demo machines. On a video call or in person, we’ll show you our robotic palletizing capabilities.

Cost: Let us help you make the business case to add automation with a comprehensive cost evaluation, including total cost of ownership and return on investment.

Engineering for You

Our Sales Application Engineers will conduct on-site consultations to listen to your goals and observe your space, applications, and workflow firsthand. Using defined production line surveying and problem-solving processes, we’ll identify critical need areas and analyze your production needs to ensure we quote all applicable equipment at the best possible prices. The result: a solution tailor-made to lower the cost of ownership and generate profitable returns for you.

Building and Installation

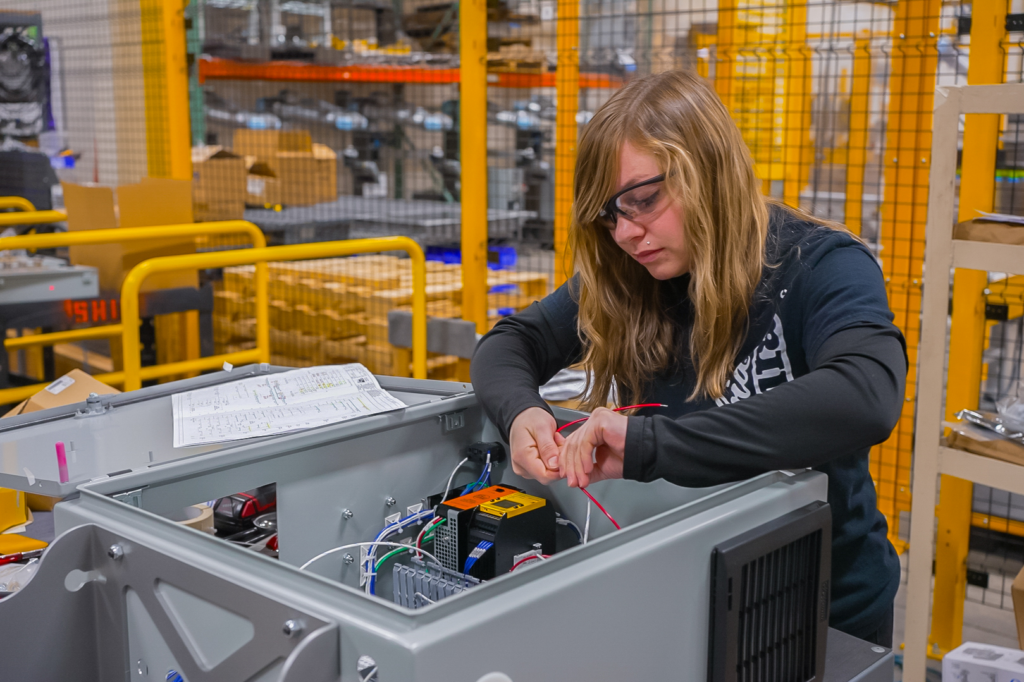

Your custom-designed system is built on our premises in Vancouver, WA. Our engineering team works very closely with our assembly team to set up and test the system with your peripheral equipment. This ensures minimal downtime during installation. Because the quality of installation affects both performance and payback, we appreciate you trusting us to be your system integration partner, allowing our certified technicians handle installation for you.

Training & Support

Initial training for system operators and maintenance personnel also takes place on our premises–before the system is installed at your facility. Training covers basic and advanced palletizer operation, advanced pattern programming, and preventative maintenance for both electrical and mechanical systems.

After installation, we remain dedicated to our partnership. Call on us to train new employees and know we’re here for you 24/7 with robust technical support.