Benefits of Robotic Palletizing Systems for Animal Nutrition

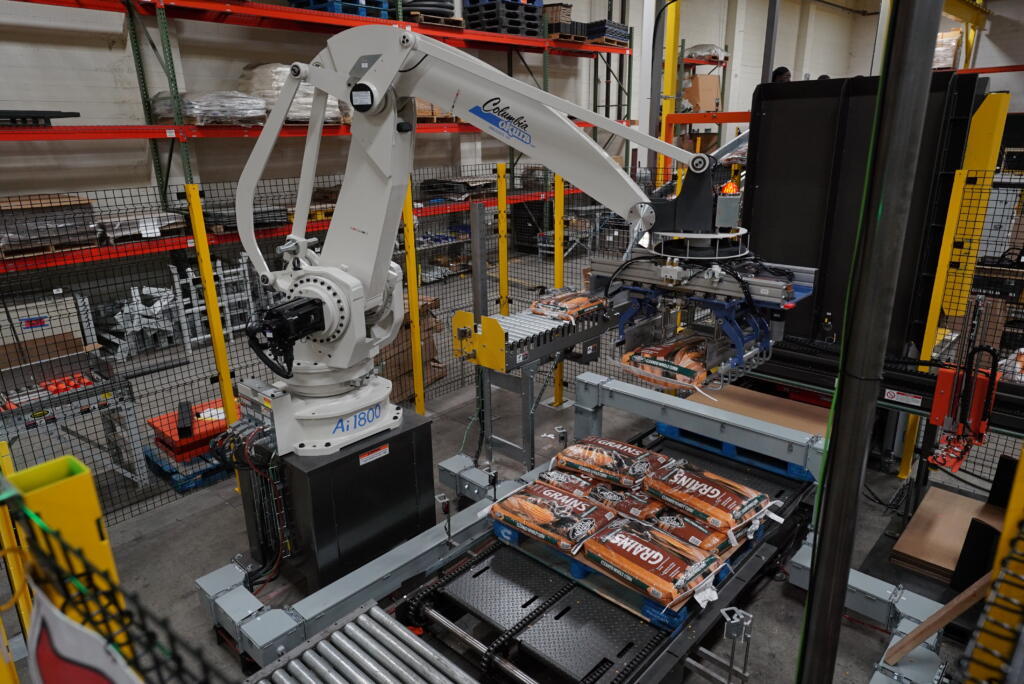

Livestock feed manufacturers can gain a competitive edge with an experienced partner in the industry that’s committed to your success. We have over 150 robots in the animal feed industry with multiple repeat customers. Flexible layouts and our custom designs will empower you to boost productivity, efficiency, and safety in your current footprint. Robotic palletizing systems also alleviate the pressure from labor shortages.

We’re proud to support the animal nutrition industry as a trusted system integrator.

Custom Solutions

We have over 150 robots in the animal feed industry. We’re able to custom design robotic palletizing systems that work efficiently and effectively within older facilities.

Bag Shaping Tools

Create secure pallets and reduce waste from damage with robots capable of overlap stacking bags. Bag shapers and push-down end effectors ensure a stable load

Solving Labor Issues

Improve efficiency while protecting employees from dusty mills and repetitive work injuries when palletizing heavy bags of animal feed weighing 50 lbs or more.

Ease-of-use

Training employees as operators takes virtually no time. Our touchscreen interface makes user-pattern programming and day-to-day use very easy.

GET STARTED ON YOUR GROWTH

Ready to meet your production goals?

Let us design a completely integrated end-of-line system that’s right for your business.

We’ll even help you develop a comprehensive plan and business case to justify the investment.

Importance of Skilled Integrators for the Animal Nutrition Industry

Bags, including woven, PP, and PE, are a common type of packaging for dry animal feed. Bagging machines, therefore, are important upstream equipment. Adjustable pushdown bag style end effectors are a huge benefit in maintaining the shape of the bags as they are placed on the pallet. Bag chutes, or adjustable bag chute conveyors for running multiple bag sizes, are also common.

Pallets of bagged, dry animal feed are typically made with overlapped stacking patterns. Stretch wrappers add stability, while checkweighers and metal detectors ensure products are contaminant-free. Our experienced team ensures all the end-of-line equipment communicates with each other to keep your production as fast and efficient as possible.

Automate Palletizing For Your Animal Nutrition Products

Barrett Pet Food invited us back to see how our integrated robotic palletizing system has changed production and increased output for their family-owned business. We can design our robots to address almost any animal nutrition application and provide turnkey, end-of-line automation for your production facility. address almost any animal nutrition application and provide turnkey, end-of-line automation for your production facility.

"THE TECHNOLOGY THEY PUT IN THE ROBOT AMAZES ME. I'M NOT A PROFESSIONAL ROBOT GUY, BUT COLUMBIA/OKURA MAKES YOU FEEL LIKE A PROFESSIONAL ROBOT GUY."

Chuck Raskin, Packaging Manager, Barrett Petfood Innovations

About Us

For nearly 30 years, we’ve been helping our customers become more competitive, cost-effective, and productive in a fast-changing world.

Our Partnership Promise

From installation to 24/7 technical trouble-shooting, you’re getting a complete support and service team you can always rely on.