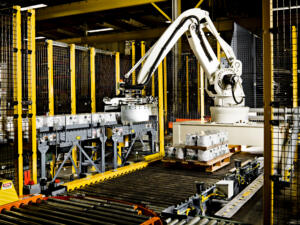

Benefits of Robotic Palletizing Systems for Agriculture

Increasing production and efficiency is challenging for the milled product industry, in part due to older facilities and labor shortages. Let us help you update your facility and bring cost-effective automation technology to your end-of-line operations.

Columbia/Okura’s automated solutions can help your facility produce more efficiently, improving your bottom line while increasing your production.

We support the agriculture industry as a trusted system integrator for all types of products, including seeds, milled grains, corn, nuts, lentils, and legumes.

Custom Solutions

Let us create an efficient system for you that fully integrates downstream and upstream, has a flexible footprint, and easily integrates with bagging machines.

Industry Experience

Trust a partner with experience in agriculture. With over 200 palletizing system installations, we are knowledgeable about this industry’s unique safety, cleaning and dust standards.

Bag Stacking Flexibility

Our robots’ capabilities include bag shaping for stable loads, as well as overlapped stacking to reduce crowning, and easy handling of 50 kg or larger bags.

Reduced Maintenance

With fewer moving parts than earlier generations from competitors, Columbia/Okura robots last longer and the operating costs can be up to half that of conventional palletizers.

GET STARTED ON YOUR GROWTH

Ready to meet your production goals?

Let us design a completely integrated end-of-line system that’s right for your business.

We’ll even help you develop a comprehensive plan and business case to justify the investment.

Importance of Bag Filling and Shaping in Agriculture Palletizing

The agricultural industry generally uses open mouth bags, filled by weight, to package bulk products. STATEC BINDER baggers are precise machines that produce filled bags with consistent weight.

After filling, bags will have a lot of empty space at the top. In most cases, they need to be flattened to make square, flat pallet loads without crowning. In some cases, however, overlap stacking patterns will create more stable pallet loads. A variety of accessories are available to create the type of pallet loads best suited for your products. Bag kickers, bag rollers, and bag flattener conveyors all condition the bags and evenly distribute the contents. Our experienced team of system integrators ensures every accessory is set up and working properly.

Michigan Sugar Case Study

Problem

Like many in the food and beverage industry, demand was building for Michigan Sugar to deliver retail display pallets. To package its sugar, the plant operates three bagging lines that together produce 150/min. The problem with retail display pallets is that customers determine the pallet pattern–and they vary. “For the display pallet experience, you need the total flexibility of a robot,” says Michigan Sugar Director of Engineering Jim Martin. “You can’t do it with a mechanical system—at least not in our facility. So that’s what drove us to our second robot.”

Solution

Michigan Sugar had been happy with their first robot purchase from us back in 2010, so they turned to us again to design and integrate a dedicated robotic palletizer for products designated for retail display. We custom-designed a high-speed robot, improving on the first design to create tighter pallets and solving for their need to fill half-pallets. “That’s one of the big things that Columbia did for us—they found a way to do the cross picks across two pallets as if they are a whole one, and then split them apart. We didn’t think that was possible, but they showed us how to do that.”

Learn how a Automation Doubled Production for Supreme Rice

Prior to introducing the dynaPAL™ system into their facility, Supreme Rice sent out two truckloads a day of product. After the installation of automation, the company sends out 50-60 truckloads a day, has been able to diversify their product offering with retail ready packaging, and has improved employee job satisfaction.

"Integrating Columbia/Okura robotic palletizers has been the best move we have made in the 21 years I have been plant manager."

Bobby Jernigan, Tennessee Farmers

About Us

For nearly 30 years, we’ve been helping our customers become more competitive, cost-effective, and productive in a fast-changing world.

Our Partnership Promise

From installation to 24/7 technical trouble-shooting, you’re getting a complete support and service team you can always rely on.

Our Palletizing Resources

Explore our blog to read case studies and more details about our robotic technology.