Benefits of Robotic Palletizing Systems for Pet Care

Keep up with the fast-changing and growing pet care industry while still delivering safe, quality products, with a partner experienced in the industry.

Let us solve your end-of-line challenges and custom design, build, and integrate a palletizing system that works with your existing equipment.

We support the pet food industry with safety-oriented automation for all types of products, including canned pet food, bagged pet food, and kitty litter.

Custom Solutions

We’re experienced in custom designing high-speed solutions that work with your existing equipment and support growth without compromising the strict regulations for animal food production.

Bag Shaping Tools

Create secure pallets and reduce waste from damage with robots capable of overlap stacking bags. Bag shapers and push-down end effectors ensure a stable load.

Reliability

Reduce downtime and boost productivity at your facility. Our robotic palletizing systems are durable and low-maintenance.

Ease-of-use

Training employees as operators takes virtually no time. Our touchscreen interface makes user-pattern programming and day-to-day use very easy.

GET STARTED ON YOUR GROWTH

Ready to meet your production goals?

Let us design a completely integrated end-of-line system that’s right for your business.

We’ll even help you develop a comprehensive plan and business case to justify the investment.

Improving Efficiency and Production in the Pet Food Industry

Whether bagged or canned, we have the handling capabilities to efficiently palletize your pet food products. Bag machines, adjustable pushdown bag style end effectors, bag chutes, and adjustable bag chute conveyors are typical integrated upstream equipment for bagged pet food that can increase throughput.

Canned cat food is often shipped in cases or wrapped trays of cans. We can multi-pick trays, helping to increase the speed of production, and use fork-style end effectors to avoid compressing the sides of trays. Downstream equipment may include barcode readers for tracking or multi-line applications.

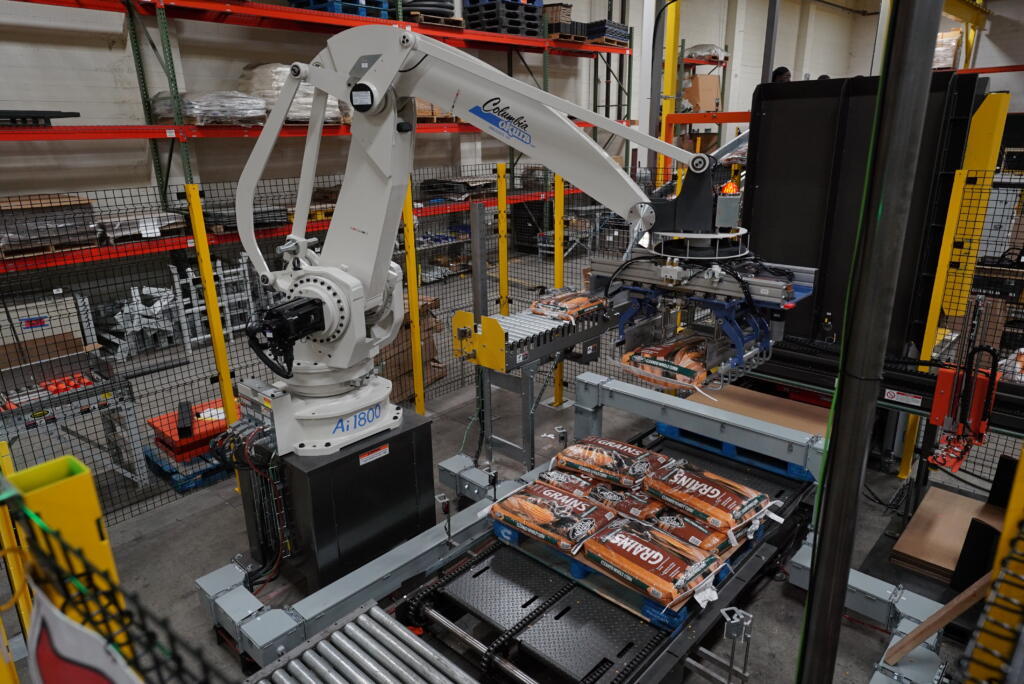

Barrett Petfood Palletizing Case Study

Solution

In early 2022, BPI installed their brand new packaging line from Columbia/Okura. This line included a robotic palletizer, STATEC BINDER Principac bagging machine, bag flattener and kicker. The result? Most bags saw a 25% to 30% increase in productivity and one bag increased 60%.

"We still have [Columbia/Okura robotic palletizing] machines running from 10 years ago. That makes me feel comfortable. We don't want to put in something that in 5 years is going to be obsolete."

Chuck Raskin

About Us

For nearly 30 years, we’ve been helping our customers become more competitive, cost-effective, and productive in a fast-changing world.

Our Partnership Promise

From installation to 24/7 technical trouble-shooting, you’re getting a complete support and service team you can always rely on.

Our Palletizing Resources

Explore our blog to read case studies and more details about our robotic technology.